The application of PVC boards in life can be said everywhere, and the use of PVC boards can produce a lot of colors close to nature. Some statistics show that in Germany, about 40% of the furniture used by households is decorated with PVC boards, such as office desks, bookshelves, sofas, various cabinets and other products.

It is not an exaggeration to say that PVC sheet is the most popular, popular and widely used component material in China and even the world. It is understood that the global usage of PVC ranks among the top among materials of various compositions, and PVC is being produced and used worldwide at an increase rate of 4%, and the increase in Southeast Asia is particularly obvious. It is because the countries in Southeast Asia have urgent needs for infrastructure construction.

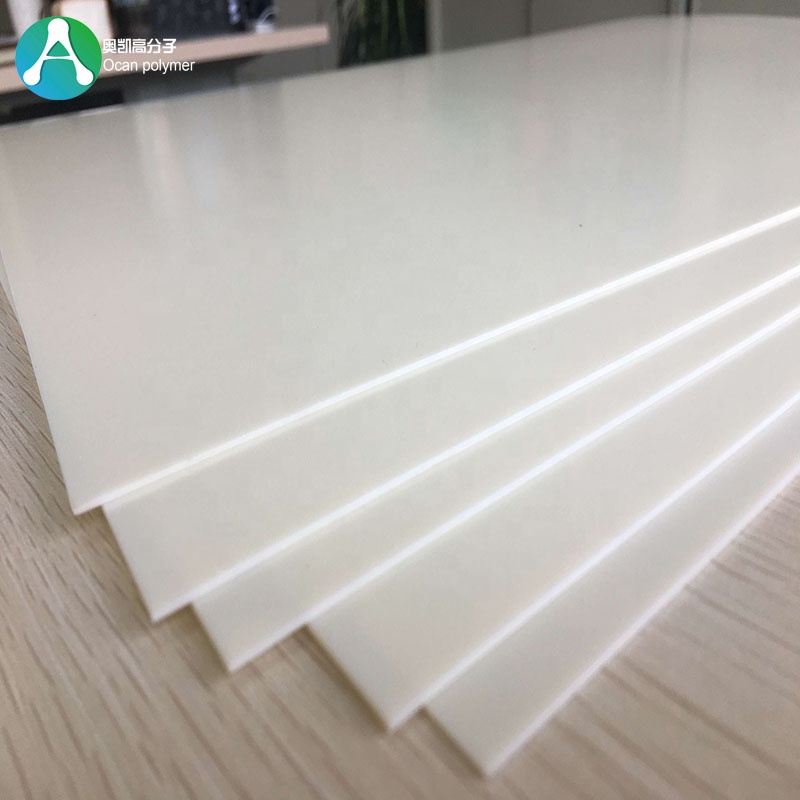

Ocan Polymer Materials produces all kinds of PVC sheets every year, and the sheet can reach about 30,000 tons, which not only meets the needs of many domestic users, but also can provide high-quality PVC sheet products to Southeast Asia, Europe and the United States.

Although PVC sheet should be widely used, it has its own disadvantages. For example, the heat resistance stability of PVC flexible board is relatively poor. It may begin to soften at a temperature of about 80 degrees. If the temperature reaches about 130 degrees, it will start to decompose and release some gases such as HCL. In addition, the electrical insulation performance of PVC is not as good as that of PP products, and it is generally suitable for low-voltage and low-frequency insulation materials.

The heat resistance of PVC flexible board is very poor. It softens at 80 degrees, decomposes at 130 degrees, and releases HCL gas. The electrical insulation of PVC is not as good as PP, and it is generally suitable for low-voltage and low-frequency insulation materials.